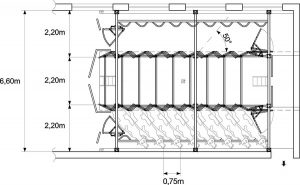

50° HERRINGBONE MILKING PARLOUR

Milking parlour that combines the solution of the herringbone milking with the one of the parallel milking. The animals are disposed at 50° in comparison to the milk hole outline, but milked with a rear milking type. The structure, available both in galvanized or stainless-steel version, with squared section tubulars, remembers the traditional herringbone milking parlour, with single splash guard and good udder visibility. The zig-zag pit edge on the straight outline of the hole grants the correct animal positioning. This is the perfect solution for people who milk in an old traditional herringbone milking parlour but in need of a new bigger one. Without any kind of building, electrical or hydraulic work, but using the same space, we are able to install the 50° milking parlour in place of the old herringbone one, managing to increase the number of stalls of a 40/50%. Our 50° milking parlour is entirely suspended and designed to be installed without the need of a temporary parlour. Our technician team will work in between the milking phases, dismantling the old parlour and installing the new one.

With the rope and pulley system we can sustain the weight of the long milk tube and also the twin tube, without binding them at the pit edge. The operator will set the length of the rope according to the udder shape ensuring an excellent balance of the cluster in order to avoid the overmilking of the anterior quarter (udder quarter). We can install this parlour both with fixed or flip-open rapid exit.

Several optional and automations are available for our 50° milking parlour to allow you to realize the one best suited to satisfy your requirements. You can contact our technical/commercial service to evaluate together your custom-made project.

Technical Characteristics

- Squared section tubulars

- Stall interaxe 75 cm

- Always suspended

- In galvanized iron or stainless steel

- Available both in-line milking parlour and two-sides

- Fixed or flip-open rapid exit

- Always inox zig-zag pit edge

- Always with upper crate for the housing of take off cylindes

- Available with traditional washing system (bowl) or forced washing system

- Available with Backflush (washing clusters after each unload of animals milked)

- Available with milk separation (dedicated milk pipeline)

- Available with electronics milk meters and computerized management system